How important is BGA assembly

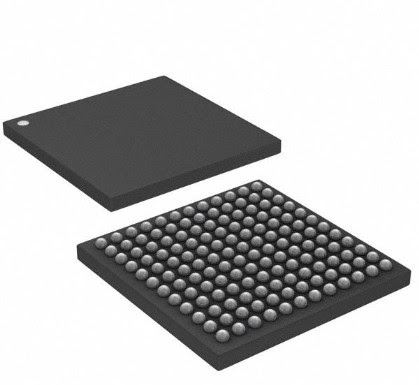

Ball Grid Array (BGA) assembly has contributed greatly to the development of electronic products in terms of performance, reliability, and miniaturization. BGA components are a type of SMT assembly that consists of a grid of metal pads on the bottom of the component package. These metal pads are connected to the internal leads of the component through small balls of solder.

Classification and characteristics of BGA components

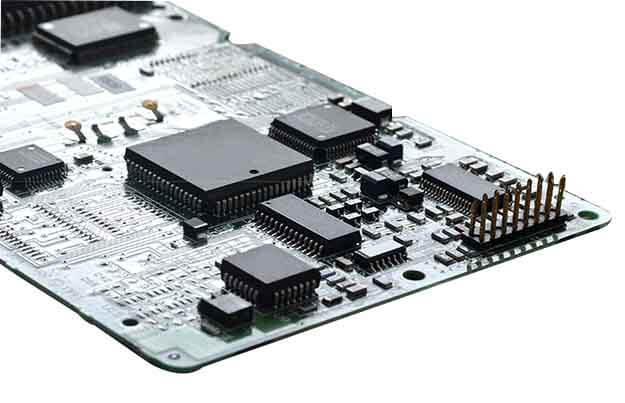

BGA (Ball Grid Array) components are a type of surface-mount technology (SMT) component that has gained widespread popularity in the electronics industry for its superior performance and compact size. In PCBA (Printed Circuit Board Assembly), BGA components are used for various applications, including computer motherboards, smartphones, gaming consoles, and other electronic devices.

BGA components are classified into two main types based on the type of solder ball used: leaded BGA and lead-free BGA. Leaded BGAs use tin-lead (SnPb) solder balls, while lead-free BGAs use a combination of tin-silver-copper (SAC) or tin-silver (Ag) solder balls.

BGA components also have various characteristics that make them ideal for PCBA applications. Some of these characteristics include:

- High Density: BGA components offer higher component density compared to other types of components, which means that they can be placed closer together on a PCB, resulting in a more compact design.

- High Performance: BGA components are designed for high-speed data transfer and can handle high levels of power and heat, making them suitable for use in electronic devices that require high performance.

- Improved Thermal Management: BGA components feature a large number of solder balls that help to distribute heat evenly across the PCB, improving thermal management and reducing the risk of overheating.

- Increased Reliability: BGA components offer better mechanical and electrical stability, as well as improved resistance to thermal and mechanical stresses, resulting in increased reliability and longer lifespan.

- Reduced Signal Noise: BGA components feature shorter signal paths, which reduces signal noise and improves signal integrity, resulting in better performance.

Contribution of BGA Assembly to Electronic Products

One of the main advantages of BGA components is their high pin density, which means that a large number of input/output (I/O) connections can be made in a small area. This makes BGA components ideal for use in high-performance applications where a large number of I/O connections are required, such as microprocessors, digital signal processors, and field-programmable gate arrays (FPGAs).

BGA components also offer better thermal performance than other types of SMT components. This is because the large number of solder balls on the bottom of the component package allows for better heat dissipation, which reduces the risk of overheating and improves reliability.

BGA components are also less susceptible to mechanical stresses than other types of components, such as quad flat packages (QFPs) and small outline integrated circuits (SOICs). This is because the solder balls on the bottom of the component provide a cushioning effect that helps to absorb mechanical shocks and vibrations.

Overall, the use of BGA components in electronic products has led to improved performance, reliability, and miniaturization, which has enabled the development of smaller, more powerful electronic devices. The BGA assembly process has also become more efficient and reliable over time, thanks to advances in technology and manufacturing processes.

Post Comment